How to Build a Wine Cellar

There are 2 types of wine cellars

- Passive Wine Cellar: No cooling equipment being used. Just the natural elements and ambient temperature.

- Active Wine Cellar: Cooling system is used to regulate the temperature and assist with humidity.

The proper temperature for long term aging of wines should be kept between 55 - 57 degrees and ideal humidity 50%-80% to prevent the corks from drying out.

Wall & Ceiling Framing

Location is an important factor to consider when building a wine cellar. Wine should be stored in a location without direct sunlight and a place where the temperature doesn't fluctuate, especially if you are planning on a Passive wine cellar. This is why many people decide on building a wine cellar in basements, closets, and under the stairs.

Build wine cellar walls using standard 2” x 4” or 2” x 6” construction methods and ceiling joist following the guidelines of local and state codes in your area. The general rule for a cellar is the thicker the walls, the better the insulation factor, the better the cellar remains at a consistent temperature.

If your location has concrete floor or walls, we recommend you apply a sealant and install your wood or tile flooring over that.

Run all necessary electrical lines and wires prior to insulation. You may need to frame out for your cooling system depending on what system you choose.

Vapor Barrier

Vapor barrier is REQUIRED if a climate control cooling unit is installed to keep the cellar at the correct temperature. The 6 mm plastic sheeting is applied to the outer warm side of the cellar walls. The vapor barrier must be either applied to the outside walls and ceiling, or if it is impossible to get to the outside, then the plastic must be applied from within the cellar over the studs. The most common method is to wrap the entire interior, leaving the plastic loose in the stud cavity so the insulation can be placed between each stud. All walls and ceiling must be wrapped in plastic for a complete vapor barrier.

This helps prevent the warm air from an adjacent room or the outside coming through the wall and hitting the cool air of the wine cellar.

****If using closed cell spray foam insulation - a plastic vapor barrier is not required since the closed cell acts as a vapor barrier.

Insulation

Insulation is REQUIRED if a climate control cooling unit is going to be used. The R-value or thickness of insulation is determined by the thickness of the walls and ceiling. For example, fiberglass insulation of R13 is designed to be used in a 2” x 4” wall and R19 is used in a 2” x 6” wall. It is important to use the correct insulation for the wall thickness. A minimum of R13 should be applied to the walls of a cellar. R19 to R32 is recommended in the ceiling.

There are 3 types of insulation: Batted, Rigid Foam Insulation, and Closed Cell Spray Foam insulation. We recommend the “closed cell spray foam” since it provides the best R-value and acts as a vapor barrier. .

This helps prevent the warm air from an adjacent room or the outside coming through the wall and hitting the cool air of the wine cellar.

****If using closed cell spray foam insulation - a plastic vapor barrier is not required since the closed cell acts as a vapor barrier.

Walls

Add moisture resistant sheetrock (green board) over the studs and insulation. The sheetrock must be installed all the way to the ground with no gaps. The racks flush against the wall so we recommend not installing a wall base where the racks will be placed.

Add your choice of wall treatment that suits your taste..Before you finish mudding, double check to make sure all air leaks in the room are sealed tight. Make sure to tightly seal and weather strip holes in your sheetrock from light switches, cooling units, power outlets, etc. You can finish your walls with latex paint, wood paneling, stone, or tile.

Most common flooring materials are wood, tile, marble, cork board, or stone.

Cellar Doors

If a cooling system is installed, an exterior grade (1¾") door must be installed as a cellar door. It is very important that weather stripping is attached to all 4 sides of the doorjamb. An auto door bottom or threshold is also recommended. The door must have a very good seal to keep the cool cellar air from escaping out of the cellar. One of the most common problems with cooling units running continually is due to not sealing the door properly. Solid core doors or doors with a full glass insert are most often used.

**** When building a wine cellar with frameless glass doors or glass walls, we recommend a load calculation to be done in order to determine the proper cooling system. In most cases, glass cellars require a stronger cooling system. The glass doors must have a proper seal to prevent cold air from leaking out. Contact us to assist with determining the proper system.

Double pane glass is highly recommended. Our Revival Glass Door line gives you the look of mostly glass while remaining double pane with a 1” bronze frame.

Lighting

Climate Controlled Systems

Through The Wall Self Contained

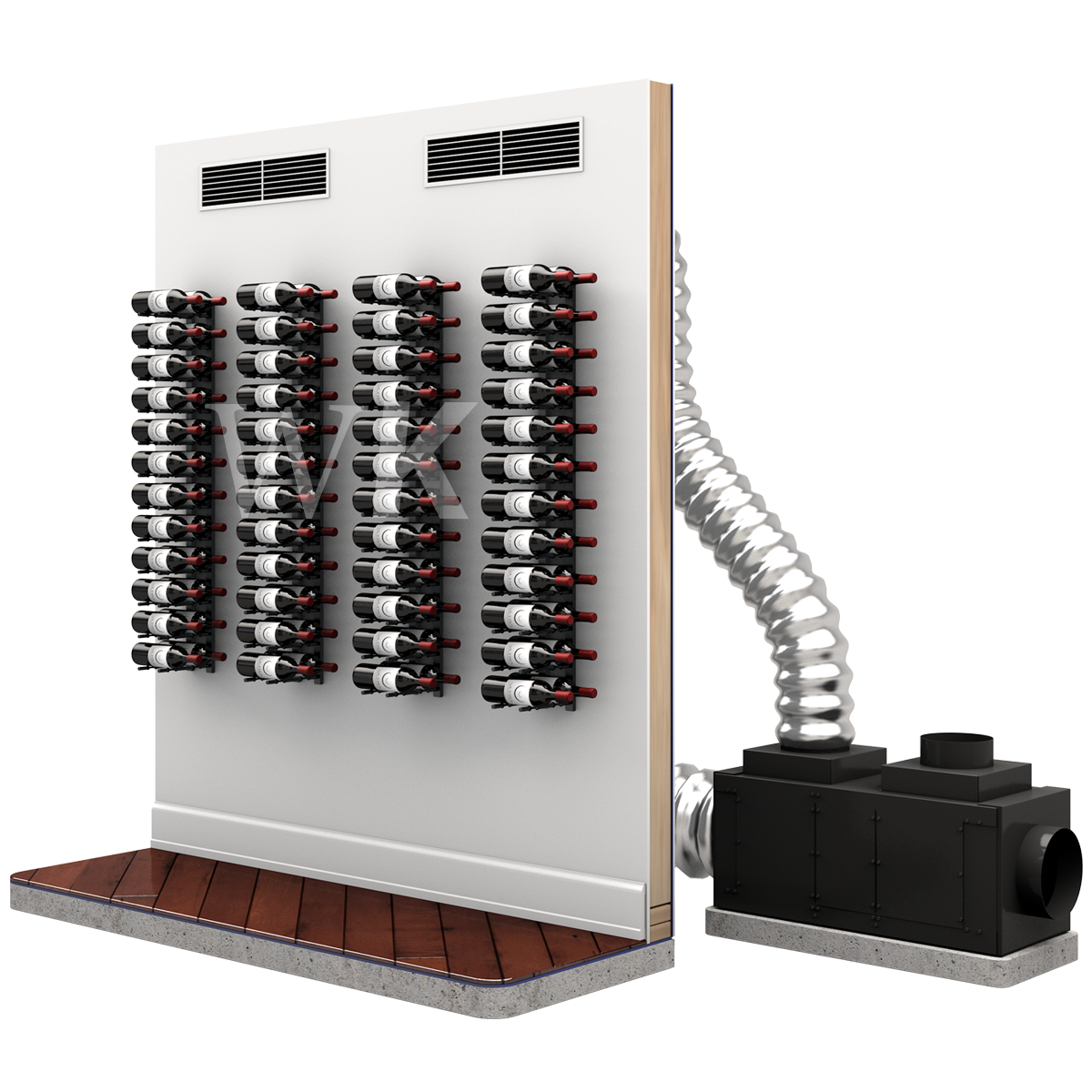

Fully Ducted Self Contained

Ductless Split System

Ducted Spit Systems

- Ventilation: The necessity of dissipating heat away from the system is critical to the unit's performance. As the unit operates and cools, an equal or greater amount of heat is generated on the exhaust side of the unit. Adequate ventilation is required in order to dissipate heat away from the unit. If ventilation is inadequate, the exhaust will heat up and adversely affect the unit's inability to cool.

- Through-Wall-Systems need to exhaust into an adjacent space, so make sure there is adequate ventilation in the room you exhaust into. This is a more economical option since it does not require any linesets or licensed as tech to install. There are systems built to vent outside and can handle up to 110 degrees ambient temperature. The coolers can be vented indoors but we recommend an area that is twice as large as the cellar, has adequate air flow, and where fan noise won’t be an issue. For smaller cabinets or closet cellars, the lower BTU cooling units made for small spaces are quieter than the coolers used for larger spaces. Some through-wall systems have ducting kits available that allow you to exhaust warm air as far as 25′ to a source of fresh air.

- Split Systems - the compressor is located outside so your wine cellar is quiet and vibration-free. Due to the use of line sets to carry refrigerant, split systems require installation by a qualified HVAC technician. Split systems are the most efficient and quiet option for wine cellars. The ceiling mount split systems have the evaporator mounted flushed in the ceiling. Split Systems can also be ordered as Ducted Split Systems. A licensed AC tech is required to install these units.

- Fully Ducted Systems - These units combine the best aspects of a split system without the added hassle and expense of installing two separate units. You can install the unit in an adjacent room, crawl space, attic so it’s quiet and vibration free in your wine cellar.

- Electrical Needs: Most systems require a dedicated 110-volt, 20-amp circuit. Some split systems require a 15-amp and a 20-amp. The system draws a large amount of amps at initial start up. By designing a dedicated circuit breaker, you will guarantee the system has enough power to run efficiently. Contact your electrician for installation of this dedicated electrical circuit. As with any sensitive electrical equipment, we suggest purchase of a surge protector because the circuitry may be damaged by power surges and spikes.